100% optical selection

It has been a challenging month, but we are glad to be back to work. Right after Easter A&B reopened its production to support our clients in the health product and other crucial supply chain.

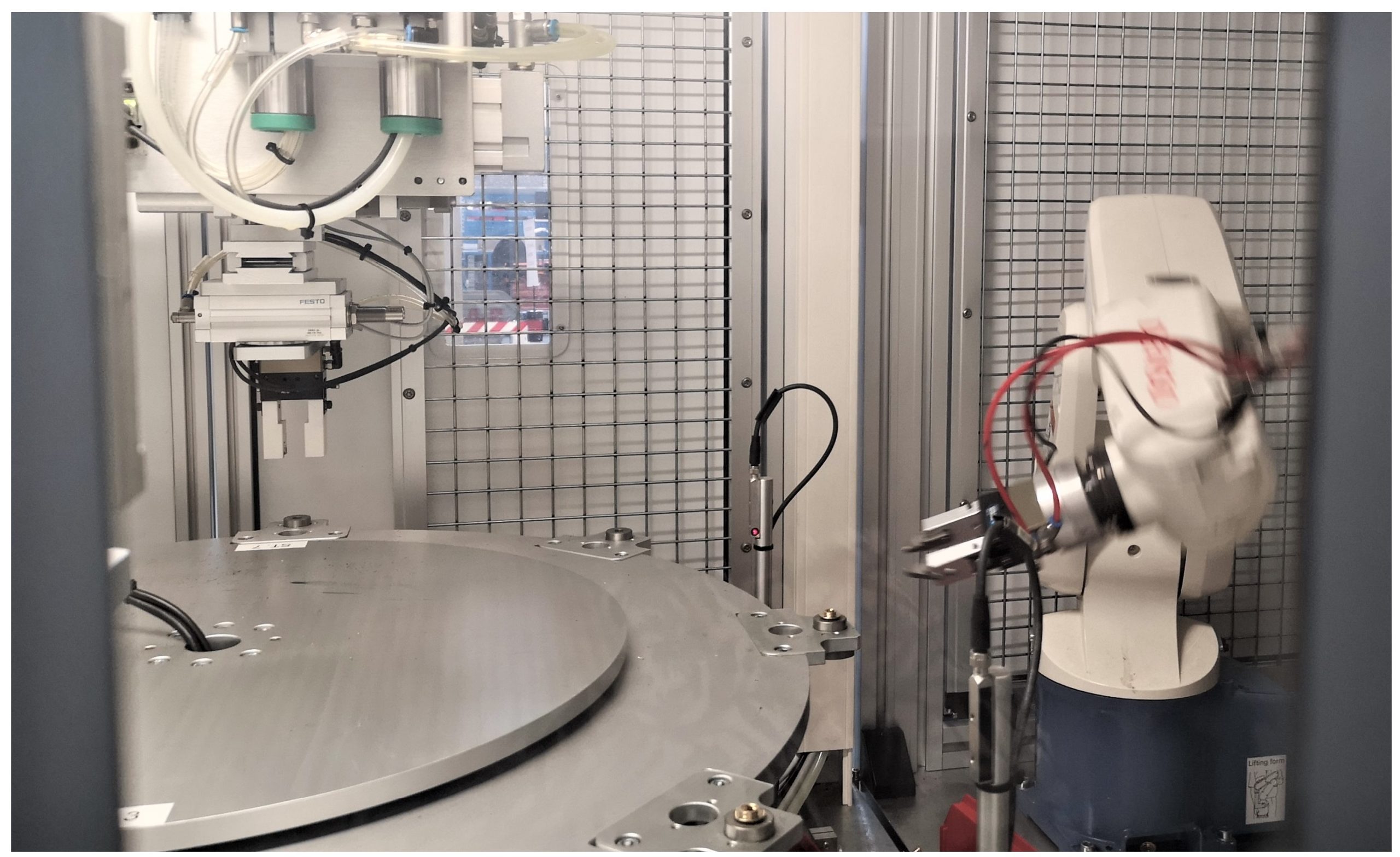

Aside from internal quality procedures, automatic selection is a key factor when it comes for such precise components. Lately we have acquired an automatic quality control optical machine to carry out 100% control checks on critical dimensions, thread presence, chips and burrs detection.

New RoHS directive aiming to a higher environmental responsibility increased the demand for low-lead brass alloys. This particular alloy – comparing to regular brass alloys – creates more chips and burrs during the turning process. Components selection and check are mostly carried out manually by an operator which can check up to 80 pieces per hour – depending on the part geometry as well.

These automatic machines can meet the most demanding PPM levels, selecting bigger quantities than an operator could manually – including 360° rotation to improve the overall quality of the process.

Vibrating screens are normally used to move parts from the turning station to the optical machine making it a less versatile way to handle different parts. In order to satisfy A&B client’s, it has been decided to replace such system with robotic arms that pick up all sort of parts different in geometry and size. A more versatile and time effective solution that meets our most demanding clients’ quality criteria.

Curious about it? Click here and send us your RFQ!

Want to read more? Check out our LinkedIn page for our past news and stay tuned for the next one to come in June!

Stay safe, stay active.